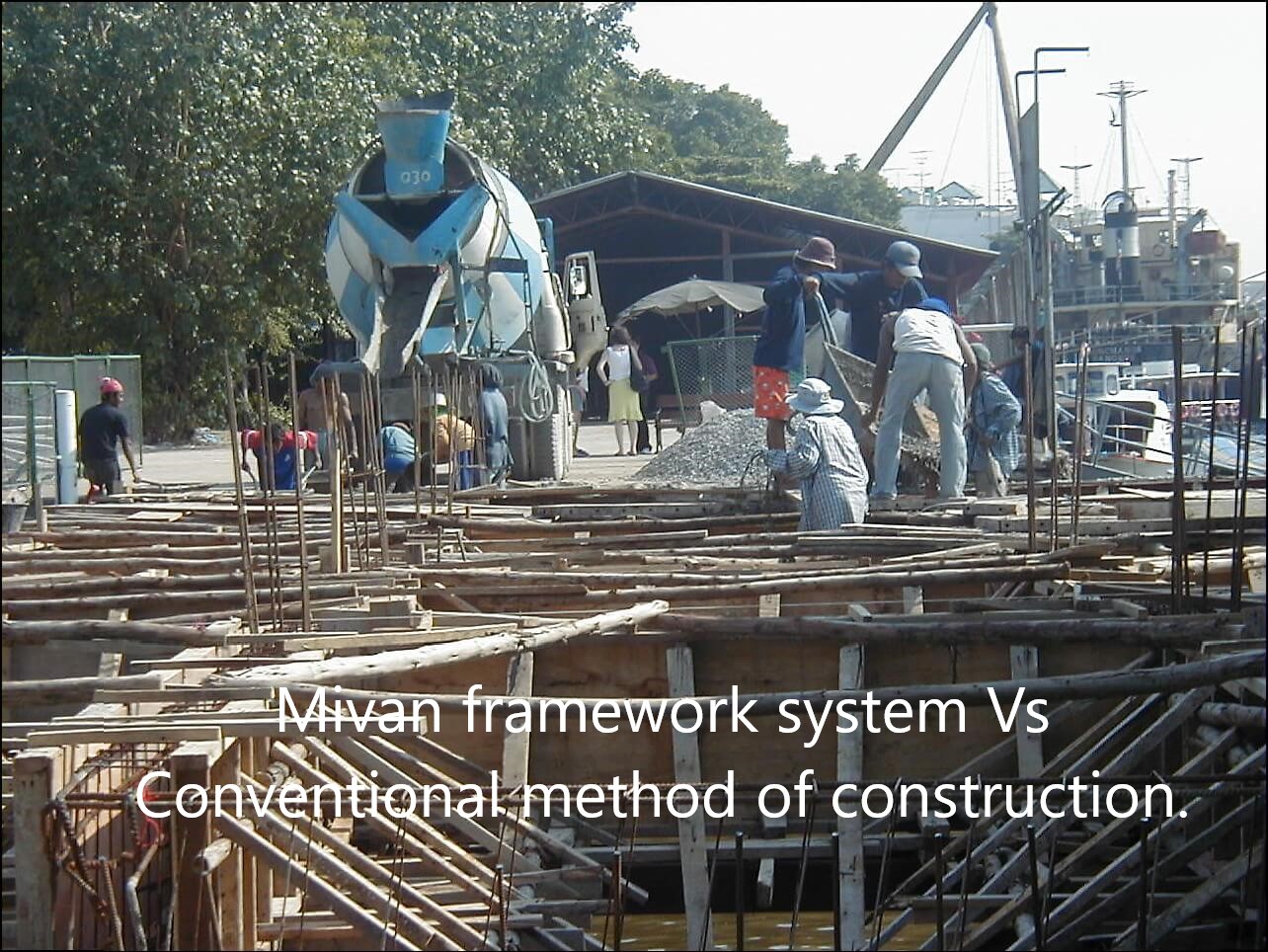

Mivan framework system Vs Conventional method of construction.

Read latest blogs and articles from Housystan

The Information mentioned here was last updated on:

25/2/2026Mivan Framework System vs Conventional Method of Construction: A Detailed Comparison

In the rapidly evolving world of construction, efficiency, speed, and quality have become critical benchmarks for success. Two dominant construction techniques—Mivan framework system and the conventional method—are often weighed against each other when evaluating large-scale projects. Each construction method brings its own set of advantages and challenges, influencing choices based on project requirements, cost, timeline, and desired finish. This article delves into the intricacies of both methods, providing insights to help industry professionals, developers, and homeowners make informed decisions.

Understanding the Basics: What is the Mivan Framework System?

- Verified Tenants/Buyers

- Unlimited Property Listing

- Zero subscription/charges fee

The Mivan framework system, pioneered by European technology in the late 20th century, has revolutionized the way modern structures are built. This system utilizes prefabricated aluminium formwork to cast entire building structures—walls, slabs, and columns—in a single process using concrete. The formwork is lightweight, easy to assemble, and reusable, making it highly suitable for projects requiring repetitive layouts, such as residential complexes and high-rise buildings.

The Conventional Construction Method: A Traditional Approach

On the other hand, the conventional method of construction, widely practiced for decades, involves the use of brick or block masonry for walls and reinforced concrete for columns, beams, and slabs. Formwork made from timber or plywood is used temporarily to shape poured concrete. This method allows greater flexibility in design but can be labor-intensive and time-consuming, especially for large-scale developments.

Speed and Efficiency: Which Method Delivers Faster?

One of the most significant differentiators is construction speed. The Mivan system stands out for its rapid turnaround time. Since the aluminium formwork is pre-engineered and assembled on site, entire floors can be cast in a matter of days. This leads to uniformity and streamlined operations, drastically reducing project timelines and labor costs. Conventional construction, while adaptable, is slower due to the sequential nature of masonry work and the curing time required for each structural element.

Quality of Construction and Finish

Quality assurance is another area where the Mivan framework excels. The system produces smooth, monolithic concrete surfaces that require minimal plastering or finishing work. The precision of aluminium panels ensures consistent wall thickness and alignment throughout the structure. In contrast, conventional construction is heavily dependent on the skill of masons and laborers, often resulting in minor variations and the need for extra finishing to achieve a perfect look.

Cost Considerations: Short-Term vs Long-Term Investments

When evaluating costs, both immediate and lifecycle expenses come into play. The Mivan system demands a higher initial investment due to the cost of aluminium formwork and skilled installation. However, its speed and reduced labor requirements can offset these expenses, particularly for projects with repetitive floor plans. Conventional construction generally involves lower upfront costs, but extended project durations and higher labor charges may increase the final outlay. Maintenance and repair costs are also lower with Mivan structures, thanks to their seamless concrete finish.

Design Flexibility: How Adaptable Are the Systems?

Architectural flexibility is an important consideration for unique or custom projects. The conventional method is highly adaptable, permitting frequent changes in design, wall thickness, and layout during the construction phase. Mivan, while ideal for repetitive and modular designs, is less flexible once the formwork has been manufactured, making it less suitable for bespoke or highly customized buildings.

Strength, Durability, and Seismic Performance

Structural integrity is a top priority in construction. The monolithic nature of the Mivan system provides excellent strength and durability, as the structure behaves as a single unit. This enhances resistance to earthquakes and lateral loads, making it a preferred choice in seismic zones. Conventional construction, though robust, may have more joints and weaker points due to separate casting of columns, beams, and walls, potentially affecting long-term durability.

Environmental Impact and Sustainability

Sustainability is gaining prominence in construction decisions. The Mivan framework system generates less waste on site due to the precision of prefabrication and minimal use of materials. The formwork can be reused multiple times, reducing the environmental footprint. Conventional construction typically results in more construction debris and requires more natural resources, such as bricks and timber, contributing to greater environmental impact.

Safety and Labor Management

Worker safety and site management are critical factors in modern construction. The Mivan system, with its mechanized assembly and reduced manual labor, lowers the risk of accidents and injuries. The methodical, standardized processes also streamline supervision and quality control. In contrast, conventional construction sites are busier, with more laborers and a greater range of on-site activities, increasing the complexity of safety management.

Applications: Where Does Each Method Excel?

The choice between Mivan and conventional methods often depends on project type. Mivan is ideally suited for mass housing projects, high-rise apartments, and any development with repetitive layouts. Its ability to deliver uniformity, speed, and strength makes it highly attractive for large-scale urban infrastructure. The conventional method remains a go-to for smaller projects, renovations, or buildings with unique architectural requirements that demand high customization.

Conclusion: Making the Right Choice for Your Project

Both Mivan framework and conventional construction methods have their merits, and the optimal choice depends on project goals, budget, timeline, and design needs. The Mivan system offers unmatched speed, quality, and durability for repetitive and large-scale developments, while conventional construction provides flexibility and adaptability for bespoke projects. As the construction industry continues to innovate, understanding the strengths and limitations of each method will empower stakeholders to deliver projects that meet the demands of the modern world.

Ultimately, the decision should balance immediate requirements with long-term value, ensuring that the chosen construction method aligns with sustainability goals, safety standards, and the evolving needs of urban living.